Editor’s note: The following article first appeared in the September 1995 issue of GCM. Because of its timeless insights for turf managers, we’ve dusted it off and are presenting it anew.

Wear is one of the two major traffic stresses on recreational turfgrass sites (7, 8), with the other being soil compaction. Wear stress is the immediate damage to turfgrass tissues caused by pressure, shear, abrasion and/or tearing as a result of both foot and vehicular traffic. Soil compaction results in long-term adverse soil conditions such as high soil strength, low soil oxygen and low water infiltration (Table 1).

Table 1. Mechanisms of turfgrass tolerance to traffic stresses

Wear. Wear is a physical injury to the tissue. Plant components that may impart wear tolerance would be those that contribute to tougher tissues, resist pressure on tissues, and/or provide more tissues (i.e., cushion).

Soil compaction. Soil compaction causes plant injury through high soil strength and/or low soil oxygen. Thus, soil compaction is really a combination of two stresses. Both of these adversely affect root development and viability. Plant tolerance mechanisms to soil compaction are complex, but they include physiological, anatomical and morphological characteristics that allow the plant to overcome high soil strength and/or low soil oxygen .

Traffic nature and intensity determine wear injury symptoms. Intensive traffic can cause immediate tearing of the sod, severe pressure/abrasion damage with rapid loss of shoot tissues, and loss of chlorophyll. Moderate traffic may cause some discoloration and slight thinning of the turf over several days.

Pressure and abrasion damage to tissues may take one or two days to be expressed. Initially, the grass exhibits a bruised (dark green), moist appearance and then turns to a blue-green, wilted condition as tissues lose water. This is followed by a loss of green within 24 to 48 hours. Upon close inspection, leaf shredding and/or wearing off of the leaves from the stem may be seen. Over several days, the stand may decline in shoot density as injured tissues die.

Turfgrass wear is favored by certain soil conditions, types of traffic, and physiological/morphological aspects of the plant (7, 8). It is important to understand the factors that enhance wear stress, as cultural programs to reduce wear involve removal of these predisposing factors (1, 7, 8, 18).

Soil factors that influence turf wear

While wear and soil compaction may occur at the same time on a site, usually one is the dominant stress. Soil conditions are most important in determining the stress that will be dominant over time. Conditions favoring wear include:

- Sandy, well-drained soils. These often resist compaction, and the soil surface tends to become dry rapidly, which increases wear potential.

- Droughty soil conditions. The soil surface is often drier than field capacity (the normal water content of a soil after drainage).

- Excessively moist soil. Surfaces with excess moisture can result in greater tearing action and shear damage.

- Compacted soils. Slower turfgrass growth and a tendency toward excessively dry or moist surface conditions are caused by compaction, which results in more wear.

- Partially thawed soil. Soil frozen at a half-inch to 1-inch depth below the surface can cause pressure damage to crowns and stolons exposed to traffic.

Traffic conditions that influence turf wear

Wear injury is directly related to the type and intensity of vehicular and foot traffic (6). Traffic conditions increasing wear injury are:

- Repeated, concentrated traffic. The pressure from one pass of a golf cart may be minimal, but when repeated 50 times a day, wear damage increases.

- High pressure per unit area. When pressure is localized and intensified, such as by tires with lugged treads or a raised shoulder on a golf shoe spike, wear is enhanced.

- Twisting. turning or slippage. A golf cart making a turn, even if not sharp, causes more damage than one traveling in a straight line.

Turfgrass status and wear stress

The physiological and morphological characteristics of the turfgrass sward at the time wear is imposed have a major influence on the degree of injury (15, 16, 17). Important plant characteristics are:

Turfgrass species/cultivar

Genetic-based differences in wear tolerance mechanisms occur across species and within a species. Examples could be inherent differences in shoot density/verdure, total cell wall content, total cell constituents (i.e., content of solutes and carbohydrates), and lignin content of cell walls. While these aspects are under genetic control, management practices also affect these factors within genetic limits.

Growth rate

Grasses that are genetically slow-growing are more susceptible to wear and are slower to recover from injury. Certainly, good management practices can influence the growth rate within limits. Winter traffic is especially damaging on dormant turfgrass (i.e., zero growth rate).

Shoot density and verdure

Shoot density is the total tissue weight or yield from the soil surface to the height of mowing. High shoot density and verdure will enhance wear tolerance. Both of these are influenced by genetics and management. A major management practice affecting shoot density and verdure is excessively close mowing — either severe scalping or mowing somewhat below the lower limit over a long period. Thatch also affects wear tolerance. Moderate thatch (1/4 inch) can enhance wear tolerance because of its cushioning effect. However, excess thatch (greater than 1/2 inch) enhances wear damage, especially from tearing action.

Turgor/moisture status of the plant tissues

Cells in the shoot tissues can resist wear damage by maintaining turgor pressure (pressure from water inside the cell against the cell walls), which is analogous to water inside a balloon exerting pressure on the balloon wall. Adequate turgor pressure is dependent on a high solute content inside cells that helps maintain water flow into cells, and sturdy cell walls that can form when the plant has adequate carbohydrates for cell wall formation and is allowed to undergo periodic mild drought stress. Cell water also binds to cell wall constituents. Solutes include inorganic salts (especially K+), carbohydrates (sugars) and amino acids.

Management practices play the major role in the turgor pressure of grasses at any point in time. For example, excessively moist conditions cause succulent cells high in water content, low in solutes and with weaker cell walls. Excessively dry conditions result in eventual water loss from the cell as well as concentration of salts in the soil, further inhibiting water uptake. Another aspect of turf cell moisture status is frosted turf. Wear on frosted turf can occur because of ice crystal damage to cells when pressure is applied, as well as some desiccation from the frost, causing tissues to be more susceptible to injury.

Preventive measures for turfgrass wear

A number of management practices can minimize wear injury. But no one practice alone is the answer. As cultural options are discussed, note how each practice deals with one or more of the soil factors, traffic conditions or turfgrass characteristics favoring wear injury (1, 7, 8, 18).

Select wear-tolerant grasses

Because turfgrasses differ in wear tolerance at the interspecific (between species) and intraspecific (within a species) levels, turf managers can use wear tolerance as a criteria when choosing a grass. Considerable literature is available on performance of turfgrasses under traffic (i.e., wear and soil compaction) using a version of Canaway’s differential slip device (4, 5, 9, 10, 11). These studies provide general insight into species/cultivar performance under traffic, but in most cases, soil compaction was the dominant stress because of the use of heavy, studded rollers and repeated passes over long time periods. However, if the study is conducted using a sandy soil and over a shorter duration to minimize compaction, wear may be the dominant stress in the study.

When reviewing research results on wear, note how this term is defined. In European literature, “wear” almost always means “traffic.” In the United States, “wear” refers only to physical wear, and “traffic” refers to the presence of both wear and soil compaction stresses.

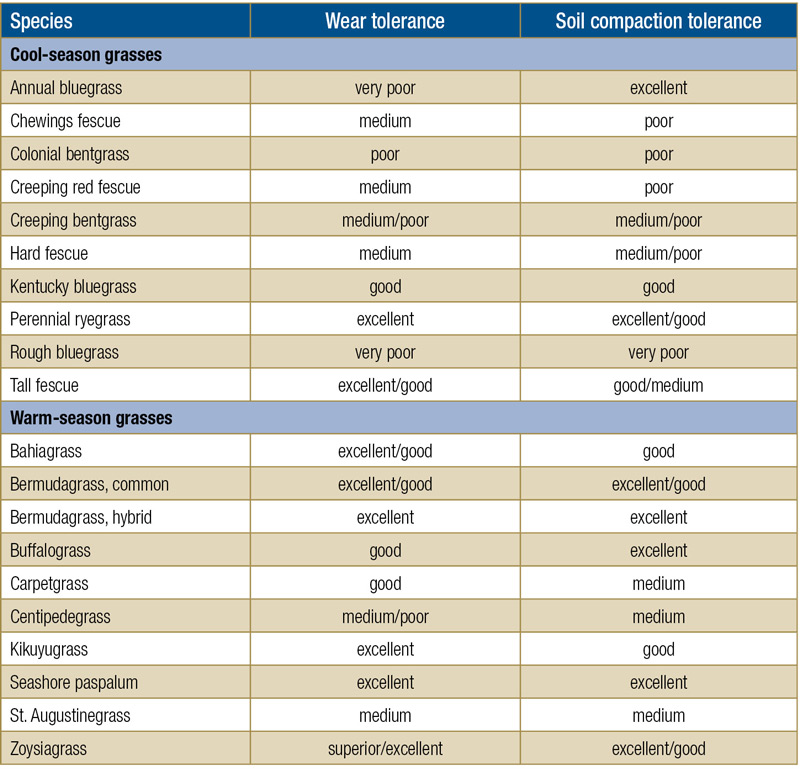

Table 2. Wear and soil compaction tolerance of turfgrasses.

General tolerance ratings at the species level are presented in Table 2, above, for both wear and soil compaction. A grass with good tolerance to one stress may not have good tolerance to the other (e.g., Poa annua, tall fescue, centipedegrass). Also, substantial cultivar differences can occur within a species.

As more specific studies identify the plant characteristics that impact wear tolerance within a species, plant breeders will be able to select or breed for these attributes. Identifying these characteristics will require research studies separating wear from soil compaction.

Traffic control

Traffic control measures are the most important components of a program to minimize wear. Several articles have been published on traffic control for golf courses (1, 12, 14) and sports turf (18). Frequently used measures are listed in Table 3. Other traffic-related items that influence the degree of wear damage are:

Type of tire

Tires with lugs, high pressure and/or low-contact surface area enhance wear injury. Pneumatic tires with wide surface areas cause less injury. Only minor differences in wear injury have been observed for different golf cart tire tread designs and radial vs. bias-ply tires (6).

Type of golf shoe (3, 13)

Golf shoes with metal spikes and shoulders around each spike result in more wear than composition soles with shorter, blunt studs.

Topdressing practices

Topdressing with sand on close-cut turf can cause physical abrasion of the grass by sand particles. This is most serious in mid- to late summer on creeping bentgrass greens. Wear can be minimized by using light topdressings that will easily infiltrate into the turf/thatch; selecting a sand in which all particles mix easily into the turf/thatch; slowly brushing or dragging in topdressing; during summer months on bentgrass, not topdressing after water injection or quad-tine (solid-tine) cultivation, but lightly topdressing a week before or after any cultivation operation; and on bentgrass in the summer, considering a lighter than normal topdressing rate.

Table 3. Traffic control measures on golf course grasses

• Design tee and green sizes to allow for frequent tee marker and cup changes, especially on heavily trafficked courses.

• Use a planned, systematic tee marker and cup rotation pattern.

• Design tees wide enough to allow markers to be moved in several different configurations across the tee width.

• Consider cart path placement carefully, especially where traffic is concentrated.

• Construct curbs on cart paths.

• Build flared ends on cart paths with a system to direct traffic in several directions off the end.

• Write guidelines to limit cart traffic during excessively wet or dry soil moisture conditions.

• Discourage golf cart operators from making sharp turns and rapid stops and starts.

• Write guidelines to limit golf carts to cart paths.

• For riding greens mowers, avoid an outside wear pattern by use of walk-behind mowers and/or shifting reels to shift tire tracks.

Traffic on dormant turf

Stolon and crown tissues can be severely worn by traffic during dormant periods. Thus, traffic control measures specific to winter months may be beneficial. These can include the use of temporary greens, alteration of the course design, guidelines for course closure when conditions favor severe wear or compaction, and frequent relocation of flags and tee markers (21).

Traffic on frozen, green leaf tissues

A unique type of wear damage occurs when traffic is allowed on frozen, green leaf tissues. Ice crystals mechanically injure cells resulting in leaf tissue loss. Withholding traffic until frost thaws is the best preventive measure. There is much published information on studies where wear is the only stress (2, 3, 6, 14, 15, 16, 17, 20, 21).

Enhancing wear tolerance

Management regimes markedly influence turfgrass wear tolerance by affecting turfgrass density/verdure, thatch level, growth rate, length of growing season, succulence, cell wall strength and cell turgidity. Potential management practices that can improve wear tolerance through these mechanisms are in Table 4.

Table 4. Cultural practices to enhance wear tolerance of turfgrasses

Promote turf density/verdure

• Mow as high as turf use allows

• Use good cultural practices to maintain turf density/verdure

• On shaded turf, mow higher, thin tree branches/trees for better light, move tee markers more frequently, and construct larger tees for shaded sites.

• Overseed dormant turf

Maintain adequate growth rate

• Correct nutrient deficiencies such as N and P

• Minimize drought, cold and high temperature stresses that limit growth rate

• Alleviate soil compaction

Avoid succulent tissues

• Provide adequate soil and air drainage

• Avoid excess N

• Avoid over-irrigation

Maintain cell turgidity (solutes + water)

• Avoid severe drought stress

• Avoid saline conditions

• Provide adequate K, neither too little nor too much

Maintain moderate thatch

• Greens (1/2 inch)

• Fairway and tees (1/4 to 1/2 inch)

• Mat (thatch plus integrated sand) is better than thatch alone

Extend the growing season where feasible

• Fall-applied N, Fe and cytokinins on warm-season grasses

• Moderate N and Fe in early spring in areas where cold injury potential is low

Potassium (K) and wear tolerance relationships deserve attention. Adequate K contributes to total cell solutes and therefore, cell turgidity. A K-deficient turfgrass tends to lose stomatal control — stomata remain open; transpirational loss of water is high; turgidity decreases; and wilt is more prevalent. Thus, adequate K is necessary, not only as a cell solute for turgidity, but also for stomatal control of transpiration. However, when K levels in the soil become excessive, high soil salinity limits plant water uptake, induces wilt, and reduces wear tolerance. Saline conditions can easily build up in sandy soils if high levels of salts are added (via fertilization and irrigation) and leaching is limited.

Common-sense guidelines for K fertilization to enhance wear and drought tolerance are:

Use soil tests to determine K needs on all soils except heavily leached sands

Soil tests provide the most accurate and predictive information on which to base fertilizer recommendations. Recommendations for K are higher on recreational sites compared with general grounds, thereby providing the extra K to enhance wear tolerance.

Leaching

On heavily leached sands (because of high rainfall or irrigation programmed to provide leaching), many growers base K fertilization on nitrogen (N) using N-K2O ratios of about 1-1 and spoon-feeding K along with N. This approach is used because soil test values for K are often low because of leaching. However, if leaching of K is not occurring, continued application of K based on a N-K2O ratio is a major contributor to soil salinity buildup.

In arid regions, turf managers often monitor total salts (salinity), but salinity can be a problem even in humid climates during dry periods when irrigation isn’t sufficient for leaching. If long-term weather patterns favor soil K accumulation, soil test for K. Many turf managers in arid climates may not be leaching a major portion of applied K, and soil tests may not always read low. These managers should consider using soil test data rather than N-K2O ratios unless they are consistently irrigating with sufficient water to leach K and other salts. In humid climates, a prolonged dry period should signal the turf manager to test for total salts and reduce K use if salts are accumulating. When the conditions of a high sand root zone mix and leaching are present, then spoon feeding K by use of N-K2O ratios is appropriate.

N-K2O

When using N-K2O ratio under the situation of sandy soils and leaching conditions, consider these adjustments:

- Use a 1-1-5 (N-K2O) ratio for annual N rates of 1 to 3 pounds N/l,000 square feet.

- Use a 1-1 ratio when annual N rates are 3 to 6 pounds/1,000 square feet.

- Use 1-0.75 or 1-0.50 N-K2O ratios at annual N rates above 6 pounds/l,000 square feet to avoid the potential of excessive salt buildup.

- In summer, apply K at 0.25 to 0.50 pound K2O/1,000 square feet spaced at two- to six-week intervals.

Alternative surfaces

Sometimes traffic is so intense that a paver or other energy-absorbing system is required. In addition to paved golf cart paths, turf managers may consider permanent concrete/plastic/ composite systems at the ends of cart paths or in temporary parking sites.

Turf recovery from wear

Turfgrass species/cultivars differ in recuperative potential. Bermudagrasses and zoysiagrasses both have excellent wear tolerance, but zoysiagrasses exhibit low recuperative potential, primarily due to their slow growth rates.

In addition to the species or cultivar, wear recovery depends on several factors, such as favorable physiological health (particularly, carbohydrate status) at the time of injury; environmental conditions conducive to recovery; cultural practices to promote recovery, especially adequate fertilization and irrigation; the degree to which traffic is limited; and alleviation of any soil compaction.

Literature cited

- Batten, S. 1986. Golf course traffic control: Maximizing revenue while protecting the turf.

Sports Turf 2(1):32, 36, 38.

- Beard, J.B., S.M. Batten and A. Almodares.1981. An assessment of wear tolerance among bermudagrass cultivars for recreational and sports turf use. Texas Turfgrass Res. 1979-1980. Texas Agricultural Experiment Station PR-3836 p. 24-26.

- Bengeyfield, W.H. 1985. Golf shoes and turf wear — a story that won’t go away. USGA Green Section Record 23(4):12.

- Canaway, P.M. 1976. A differential slip wear machine (D.S.1) for the artificial simulation of turfgrass wear. Journal of the Sports Turf Research Institute 52:92-99.

- Canaway, P.M., and others. 1981-present. Sports Turf Res. Inst. Journal and Annual Turfgrass Seed Reports Pub., Sports Turf Research Institute, Bingley, West Yorkshire, UK.

- Carrow, R.N., and B.J. Johnson. 1989. Turfgrass wear as affected by golf car tire design and traffic patterns. Journal of the American Society for Horticultural Science 114(2):240-246.

- Carrow, R.N., and A.M. Petrovic. 1992. Effects of traffic on turfgrass. In: D.V. Waddington, R.N. Carrow and R.C. Shearman (eds.). Turfgrass Monograph 32, American Society of Agronomy, Madison, Wis.

- Carrow, R.N., and G. Wiecko. 1989. Soil compaction and wear stresses on turfgrasses: Future research directions. Proceedings of the 6th International Turfgrass Research Society Conference, Tokyo. International Turfgrass Society, Belle Glade, Fla.

- Cockerham, S.T., V.A. Gibeault, J. Van Dam and M.K. Leonard. 1990. Tolerance of several cool-season turfgrasses to simulated sports traffic, natural and artificial playing fields: Characteristics and safety features. p. 85-95. In: R.C. Schmidt, E.F. Hoerner, E.M. Milner

and C.A. Morehouse (eds.). American Society for Testing and Materials STP 1073, Philadelphia.

- Cockerham, S.T., V.A. Gibeault, J. Van Dam and M.K. Leonard. 1991. Traffic tolerance of

cool-season turfgrasses. Golf Course Management 59(8):44-51.

- Dunn, J.H., D.O. Minner, B.F. Fresenburg and S.S. Bughrara. 1994. Bermudagrass and cool-season turfgrass mixtures: Response to simulated traffic. Agronomy Journal 86:10-16.

- Gast, C. 1991. Learning to live with golf cart traffic. USGA Green Section Record 39(5):9-11.

- Gibeault, V.A, V.B. Youngner and W.H. Bengeyfield. 1983. Golf shoe study II. USGA

Green Section Record 21(5):1-7.

- Oatis, D.A. 1994. Common sense cart paths. USGA Green Section Record 32(1):1-5.

- Shearman, R.C., and J.B. Beard. 1975. Turfgrass wear tolerance mechanisms: I. Wear tolerance of seven turfgrass species and quantitative methods for determining turfgrass wear injury. Agronomy Journal 67:208-211.

- Shearman, R.C., and J.B. Beard. 1975. Turfgrass wear tolerance mechanisms. II. Effects of cell wall constituents on turfgrass wear tolerance. Agronomy Journal 67:211-215.

- Shearman, R.C., and J.B. Beard. 1975. Turfgrass wear tolerance mechanisms. III. Physiological, morphological, and anatomical characteristics associated with turfgrass wear tolerance. Agronomy Journal 67:215-218.

- Shearman, R.C. 1989. Improving wear tolerance of sports turf. Grounds Maintenance

24(1):84-85, 104-106.

- Snow, J.T. 1987. Politics, religion, and winter play on greens. USGA Green Section Record 25(6):1-4.

- Youngner, V.B. 1962. Accelerated wear tests on turfgrasses. Agronomy Journal 53:217-218.

- Youngner, V.B. 1962. Wear resistance of cool-season turfgrasses. Effects of previous

mowing practices. Agronomy Journal 54:198-199.

Robert N. Carrow is a professor of turfgrass science in the agronomy department at the University of Georgia Agricultural Experiment Station in Griffin, Ga.