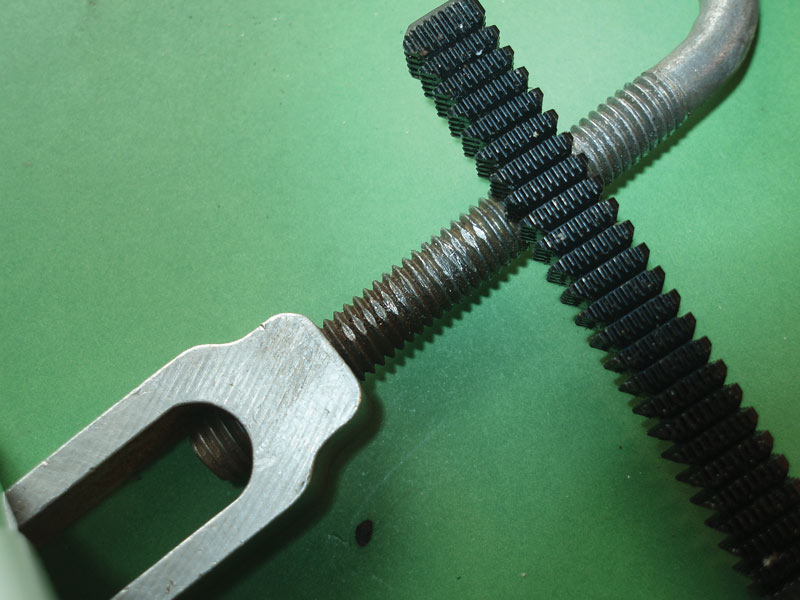

These threads were returned to usable condition in just a few seconds via a thread restoring file. Photo by Scott R. Nesbitt

Dad’s toolbox included a weird kind of file that had eight different file faces but was pretty useless for shaping wood or metal. A few weeks ago, browsing an industrial surplus liquidator, I saw the same type of file in a nice, new package and finally learned what it was: an external-thread restoring file. Sixty some years later, I now realize that I should have asked Dad what it was, and that every technician needs one — or maybe four of them — in every toolbox.

The photo above shows patches of damaged threads on each side of some good threads. The damaged threads were repaired in under 30 seconds using that surplus “thread chaser” file that brought back memories of boyhood tinkering and all the hassles I’d have avoided for several decades if only I’d asked Dad about that odd tool.

The thread repair is simple: Determine the file face that matches the threads, and pull back lightly to “feel” the proper angle across the threads. Apply modest pressure while pushing the file forward, and no pressure on the return stroke. Check your work every five or six strokes.

Before finding my file, I’d have spent maybe a half-hour cleaning the threads with a tiny jeweler’s file, or wasted time, fuel and cash fetching a new turnbuckle from the hardware store. Using tools from the tap-and-die set wasn’t an option, because those are left-hand 3/8-16 threads, and I don’t have that die.

My file has a square shaft, 7/16 inch on each side, and is 8 3/8 inches long. There are eight file segments, each labeled for a specified threads-per-inch (TPI) count: 11, 12, 13, 14, 16, 18, 20 and 24. Those TPI counts are used on U.S. standard fasteners from 1/4- to 5/8-inch shaft diameter.

Restoring files are also made for metric threads, with spacings of 0.80, 1.0, 1.25, 1.5, 1.75, 2.0, 2.5 and 3 millimeters. Another is designed for U.S. pipe threads, and another handles extra-fine and extra-coarse U.S. threads. There are files for threads used on hydraulic hose fittings, and others for Whitworth thread system fasteners used on old British Empire machinery.

The biggest challenge in using one of these files is making absolutely sure you match the file to the threads you’re restoring. Using the wrong file face will only cause more damage. Eyeball the thread/file matchup in strong light. If you can’t see that damaged exhaust manifold stud, match the file to a companion stud, or use a light touch with the file.

If the flawed fastener is in a high-stress situation, such as a connecting rod bolt or something in the steering system, employ safety-first thinking and invest in a new bolt. For most fasteners in most settings, though, it’s fine to clean up some damage or remove rust and crud from the threads and then get on with the job without hauling back to the shop for parts or something from the tap-and-die set.

Despite the obvious usefulness of these files, I couldn’t find a single one on display at any big-box, hardware or auto/tractor/truck parts retailer I haunt, nor do I recall any tool truck salesman pushing me to buy a set. The best bet is to go online, where even office supply stores stock the files.

The Nicholson 33024 set of four files, priced at $51.52, seems to be the most common offering. Diligent searching turned up comparable files for $10 apiece. Some proud tool suppliers want a whole lot more for files with the same dimensions and thread faces. Shop wisely, and enjoy.

Scott R. Nesbitt is a freelance writer and former GCSAA staff member. He lives in Cleveland, Ga.