Some equipment service chores are too easily ignored. Tackling them during the dull, damp days of winter can reduce the chances that deferred maintenance will cause a warm-weather calamity.

Hydrostatic transmissions are nearly universal on turf machinery, thanks to the simplicity of controlling speed and direction. But machines also have to stop. When properly adjusted, the hydrostatic machine usually stops when you release the control handles. But “usually” isn’t good enough. Most hydrostatic transmissions have a separate braking system that must be maintained and adjusted. Typically, this is simple — the hard part is gaining access, as the transmission is at the core of the machine.

The photo above shows the rust and debris that had built up over one year on the two round steel plungers mounted in a cast-iron holder. These plungers press on a brake pad that grips the brake disc mounted on the splined shaft at the rear of the photo. It took propane-torch heat, penetrating oil and a hammer and punch to take the system apart and remove the rust. Drum brake grease was applied in the hope that it will keep the plungers sliding instead of seizing.

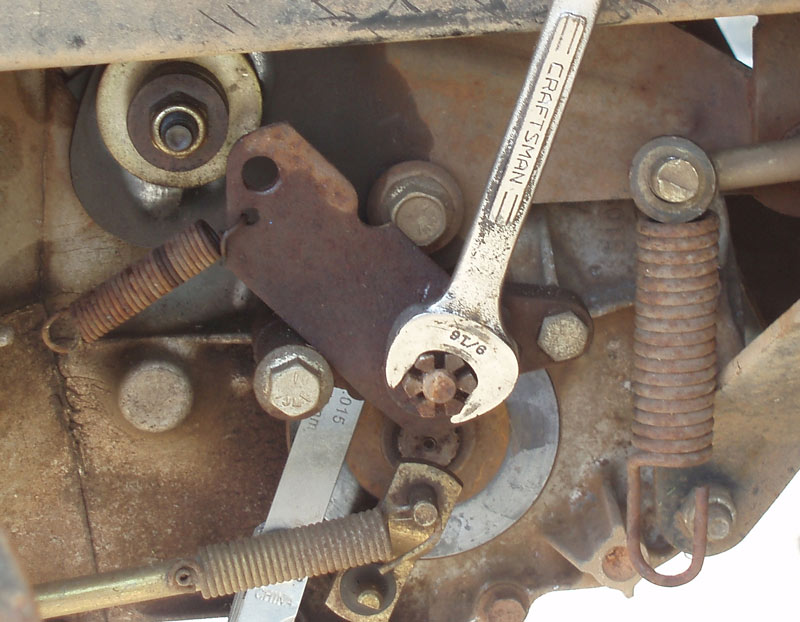

After it has been cleaned and lubricated, adjusting the hydrostatic transmission brake system (photo above) is simple. Insert a 0.015 feeler gauge between the disc and the brake pad, tighten the central nut with a wrench, and then loosen until the feeler gauge drops out. Install a cotter pin to hold the nut in position.

Some hydrostats use a brake disc that has teeth on the outer rim, with a brake arm with teeth that engage the disc’s teeth. Others use a band that grips the outer rim. Adjustment methods will be specified in the service manual.

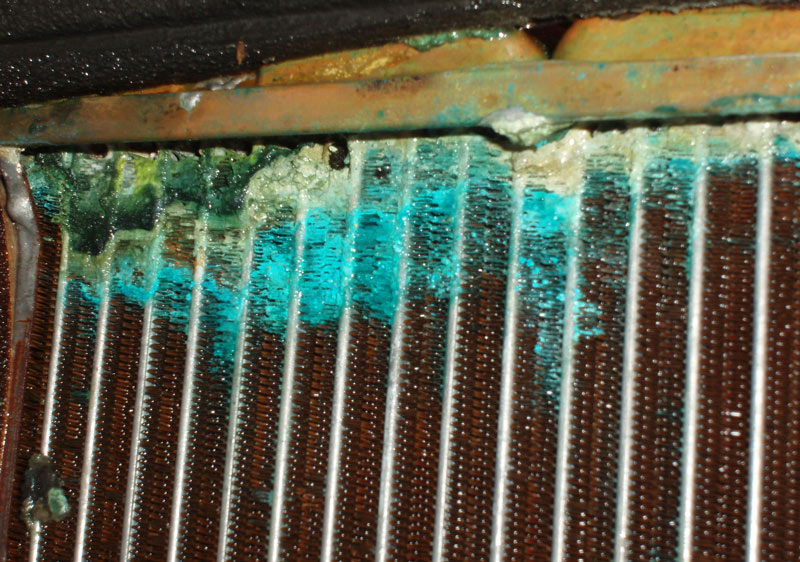

Cold weather also presents a good time to replace the coolant in all off-road and on-road vehicles. The radiator shown above was destroyed by the use of the wrong antifreeze chemicals. Please read the owner’s or repair manuals, and use the coolant that’s absolutely required by the equipment manufacturer. There is no universal antifreeze. Use the stuff the machine-maker specifies, change it on schedule, and follow service manual procedures.

Before checking and replacing coolant, purchase “permanent” coffee filters (shown above) to trap debris that would get into the cooling or lubrication system. Nylon filters cost $3 or less, while $6 will buy a filter made of stainless steel coated with gold.

Finally, check with your city, county or state regulators to find how and where to take old antifreeze for recycling. It’s considered hazardous waste.

Scott R. Nesbitt is a freelance writer and former GCSAA staff member. He lives in Cleveland, Ga.